-

Fallstudie | Sinexcel Aktivfilter wurden erf...

2023-09-07

-

Sinexcel bewirbt großartig 40~120KV...

-

Sinexcel SVG unterstützt die Photo...

-

Seien Sie einfacher, effizienter | S...

-

Sinexcel beschleunigt Accenture dabei,...

-

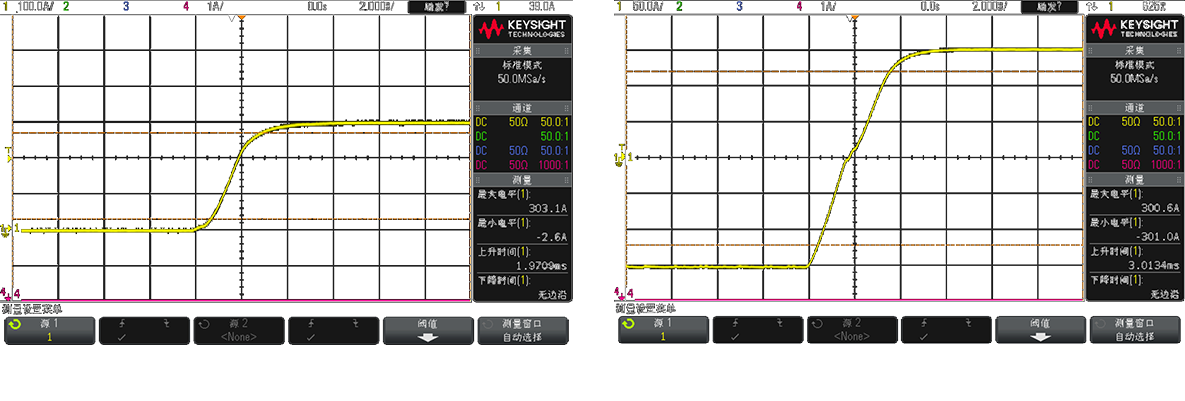

10.000.000 Ampere Verkäufe!!! Recor...

-

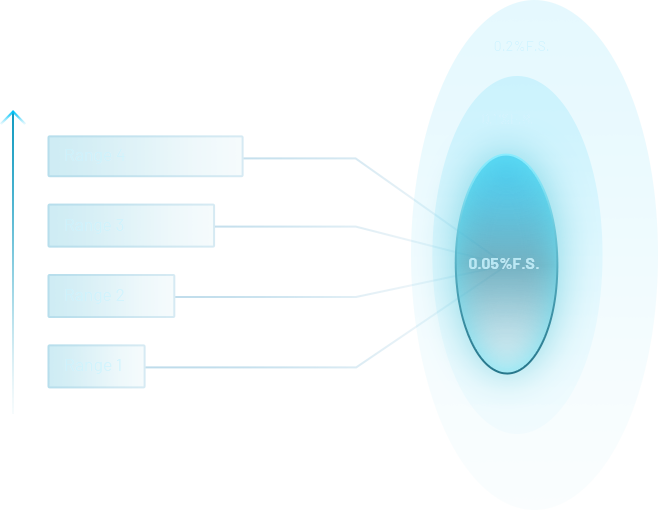

Die Sinexcel PRO Active Harmonic...

-

Sinexcel UPS installiert in Jingdez...

-

Fallstudie | Sinexcel DC-Ladegerät integri...

2023-08-23

-

Sinexcel und Rolec kooperieren bei der...

-

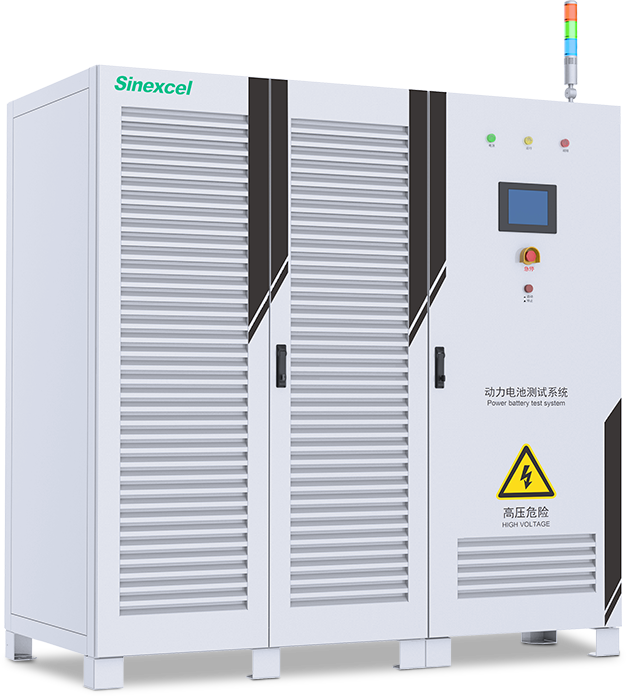

Sinexcel, Weltmarktführer im Berei...

-

Sinexcel auf der Power2Drive Europe...

-

Das Sinexcel Interstellar AC-Ladege...

-

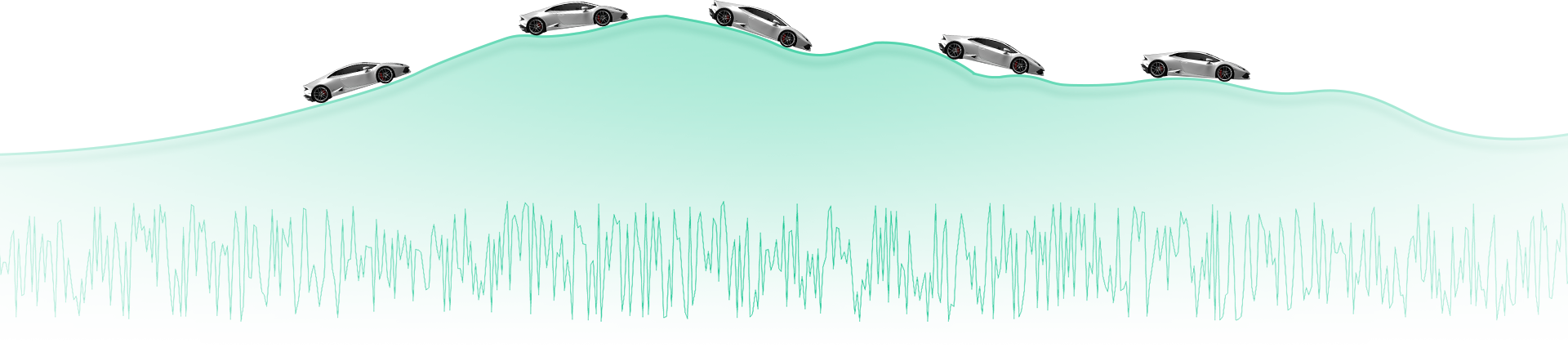

22 kW Interstellar, ein neues AC-Lad...

-

Energy storage micro network to build...

-

Sinexcel wird Kernmitglied von Char...

Interstellar AC Charger - Innovativ, ...

Die Geschichte hinter dem Interstella...

Wie richtet man eine öffentliche Lad...